GPT-4 can exploit security flaws on its own, study shows

At least once a week, generative AI finds a new way to terrify us. We are still anxiously awaiting news about the next large language …

At least once a week, generative AI finds a new way to terrify us. We are still anxiously awaiting news about the next large language …

Apple just released iOS 17.5 beta 3 to developers. This might be Apple’s last iOS 17 update for iPhone users before it unveils iOS 18 during the WWDC 2024 keynote …

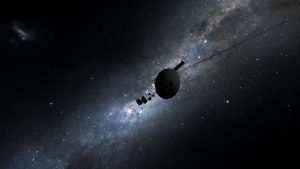

After five months of gibberish, Voyager 1 is finally talking to NASA again. The 46-year-old probe randomly started submitting funky data to NASA back in …

iPad users rejoiced once Apple introduced the Weather app in 2022 with iPadOS 16. However, another iPhone software was still missing from this release, which …

The Samsung Galaxy Tab A8 tablet is one of the best all-around tablets that Samsung makes. It’s the ideal balance between price and performance, giving …

Apple usually holds spring events. With several rumors about new products, the company may be considering a presentation for the next month before it unveils …

Today, Apple announced a special event for May 7. The company will likely announce the new iPad Pro, iPad Air, Apple Pencil 3, and Magic …

There are so many great daily deals out there on Tuesday that we almost don’t know where to start. How about popular Nooie smart plugs …

Sonos has always been one of the companies that supports a heck of a lot of audio-based services. From music streaming services to podcast players …

Over the weekend, a leaker declared that FineWoven cases were done, and Apple would move on to a new fabric for its premium cases. Surrounded …

Apple’s AirPods 3 are among the most popular earbuds out there right now. That’s to be expected, of course, since AirPods are super popular in …

For being as necessary as they are to the orderly functioning of society, policemen and women in the US are some of the most convenient …

While we wait patiently for the return of Amazon’s Rings of Power and a whole new series of Lord of the Rings movies, Wētā Workshop …

On Friday, April 5, Apple upended years of precedent by updating its App Review Guidelines to allow retro game emulators on the App Store. Less …

Given the creeping encroachment of AI into almost every aspect of modern life — from making music to helping Google maintain even more of a …

The top show on Max right now isn’t the last season of Curb Your Enthusiasm, The Jinx − Part Two, or The Sympathizer. No, the …

Since PlayStation announced PS VR years ago, rumors of a virtual or mixed-reality headset coming from Xbox have swirled. With Meta’s latest announcement, that dream …

Scientists have watched two lifeforms merge in a once-in-a-lifetime evolutionary event. The event is so rare that scientists say it has only ever happened twice …

Early reports suggest iOS 18 is going to be packed with AI features, and Apple is continuously hinting at that. We’ve seen published papers, CEO …

I’m getting more strategic than ever with the TV shows I stream these days, largely because there’s just so much available across all of the …

Launched on November 1, 2019, Apple TV Plus is home to Apple’s original TV shows, movies, and documentaries. With an award-winning catalog, users can stream …

Nintendo just hosted its Indie World Showcase on April 17th to highlight a ton of indie games coming to the Nintendo Switch this year, and …

AirPods are unquestionably among the most popular headphones in the world. It’s great that there’s so much variety in the Apple AirPods lineup, but the …

iOS 18 will be available with a handful of new AI features. At least, this is what the latest reports and rumors believe. In his …

With new iPad Air and iPad Pro models expected for early May, the inventory for the Air lineup seems to be dwindling. Usually, when Apple …

When it comes to dedicated health and fitness trackers, everyone knows that Fitbit is as good as it gets. Plus, newer Fitbit smartwatch models offer …

I don’t know if there has ever been a movie that I’ve anticipated more than the one that is coming out on July 26th. Maybe …

With the iPhone 15 rumor cycle, it was expected that Apple could add capacitive buttons to this device. This means the company would remove the …

The shopping experts at BGR Deals are off to a flying start on Monday, with some of the hottest deals of the season having popped …

It seems Apple’s M3 Mac lineup is almost complete, as the company might be planning to skip an M3 Mac mini in favor of a …

Apple introduced FineWoven accessories with the iPhone 15 release. In its goal for a carbon-neutral company by 2030, Cupertino ditched all its leather accessories in …